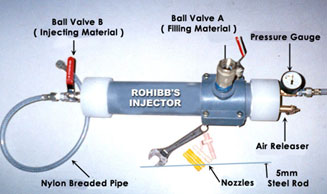

ROHIBB’S INJECTOR

For Epoxy / Polymer Injection In Concrete

This is a unique device to inject low viscosity epoxy resin system into cracks in concrete structures, under air pressure not exceeding 4-5 Kgs/cm2 ( approximately 100 lbs/inch2 ).

The device consists of a cylinder containing a smoothly moving piston also made of Nylon and a actuated by air pressure. The cylinder is closed at both ends by screwed caps. The front side contains a ball valve and a braided nylon hose with screw on nozzle. The back side contains a pressure gauge, air release valve and a nozzle for connection to the air compressor or foot pump.

Stepwise Procedure for Grouting

The epoxy resin

and hardener are mixed as per manufacturer’s specifications and poured into

the cylinder by using funnel and opening the ball valve (A). Instead of epoxy system, monopol system ( High

molecular Polymer - LV Grade, SLV Grade ) can also be poured into the

cylinder.

After filling the

cylinder to its rated capacity, the nylon breaded pipe is screwed on the

nozzle on the concrete surface. Now the device is held at an angle of

approximately 45° to the horizontal.The air compressor or foot pump is used

for the material in the cylinder to be pressurized taking care to see that the

pressure is initially not more than 2-4 Kgs/cm2.

If the

cylinder is used continuously, it should be cleaned along with the ball valve,

the connecting hose etc,

with T-50 thinner by

flushing.

|

Precautions : Operator should use Safety goggles, Breathing mask, and Helmet along with hand gloves. After each operation, release the air carefully through the air releaser before opening the ball valve for refilling / cleaning. To prevent leakage, apply teflon tape ( PTFE Threadseal Tape ) |

5-B, Mohsin Bldg, R.K.

Vaidya Rd., Dadar (w), Mumbai - India 400 028

Tel:

022-24303820 , 022-66669144 email: rohibbs@yahoo.com